Building a better milk van

I've started a second attempt at my little milk van. I mentioned before that I was unhappy with certain aspects of it, specifically the lack of fit of the body and chassis :) So this time I started off with the chassis (the same one as before) and designed the body to fit on it.

First, though, the chassis needed a tidy-up. The floor had to be extended (with 40 thou plasticard) to match the lengths of the solebars, and I cut buffer beams from 30 thou plasticard. A bit of trimming and the ends matched up nicely ;)

First, though, the chassis needed a tidy-up. The floor had to be extended (with 40 thou plasticard) to match the lengths of the solebars, and I cut buffer beams from 30 thou plasticard. A bit of trimming and the ends matched up nicely ;)

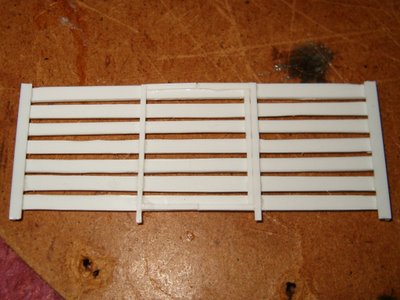

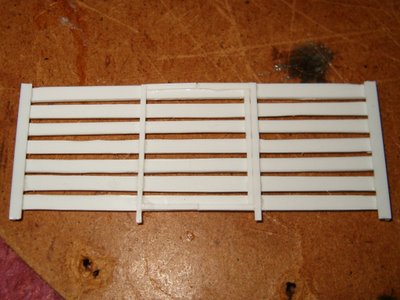

From investigation, I decided that the "ironwork" on the sides and ends of the wagon should fit tightly to the outside of the floor and buffer beams. Thus the side planks should be exactly the same length as the wagon. I cut them first (seven of them), then stuck them to the corner mouldings. The sides are still 30 thou, I still can't cut straight, but the spacing is far better than before as I fitted them one-by-one using a sliver of 30 thou plasticard as a spacer. I also decided I'd have a gap just above floor level, as I thought it would look nice - I don't know if it's authentic, but I think cattle wagons have them, and it would help wash out spilt milk.

With one side built, I have started to put on the "ironwork" and door framing. This time I used 20 thou cut to 1mm widths (however inaccurately). The wagon has double doors which go from floor to ceiling. This surprised me slightly: I might have expected the bottom of the doors to fold down into a ramp, but my Siphon G doesn't do that and it would be harder to do so forget it ;)

With one side built, I have started to put on the "ironwork" and door framing. This time I used 20 thou cut to 1mm widths (however inaccurately). The wagon has double doors which go from floor to ceiling. This surprised me slightly: I might have expected the bottom of the doors to fold down into a ramp, but my Siphon G doesn't do that and it would be harder to do so forget it ;)

More on this project when it happens.

First, though, the chassis needed a tidy-up. The floor had to be extended (with 40 thou plasticard) to match the lengths of the solebars, and I cut buffer beams from 30 thou plasticard. A bit of trimming and the ends matched up nicely ;)

First, though, the chassis needed a tidy-up. The floor had to be extended (with 40 thou plasticard) to match the lengths of the solebars, and I cut buffer beams from 30 thou plasticard. A bit of trimming and the ends matched up nicely ;)From investigation, I decided that the "ironwork" on the sides and ends of the wagon should fit tightly to the outside of the floor and buffer beams. Thus the side planks should be exactly the same length as the wagon. I cut them first (seven of them), then stuck them to the corner mouldings. The sides are still 30 thou, I still can't cut straight, but the spacing is far better than before as I fitted them one-by-one using a sliver of 30 thou plasticard as a spacer. I also decided I'd have a gap just above floor level, as I thought it would look nice - I don't know if it's authentic, but I think cattle wagons have them, and it would help wash out spilt milk.

With one side built, I have started to put on the "ironwork" and door framing. This time I used 20 thou cut to 1mm widths (however inaccurately). The wagon has double doors which go from floor to ceiling. This surprised me slightly: I might have expected the bottom of the doors to fold down into a ramp, but my Siphon G doesn't do that and it would be harder to do so forget it ;)

With one side built, I have started to put on the "ironwork" and door framing. This time I used 20 thou cut to 1mm widths (however inaccurately). The wagon has double doors which go from floor to ceiling. This surprised me slightly: I might have expected the bottom of the doors to fold down into a ramp, but my Siphon G doesn't do that and it would be harder to do so forget it ;) More on this project when it happens.

0 Comments:

Post a Comment

<< Home